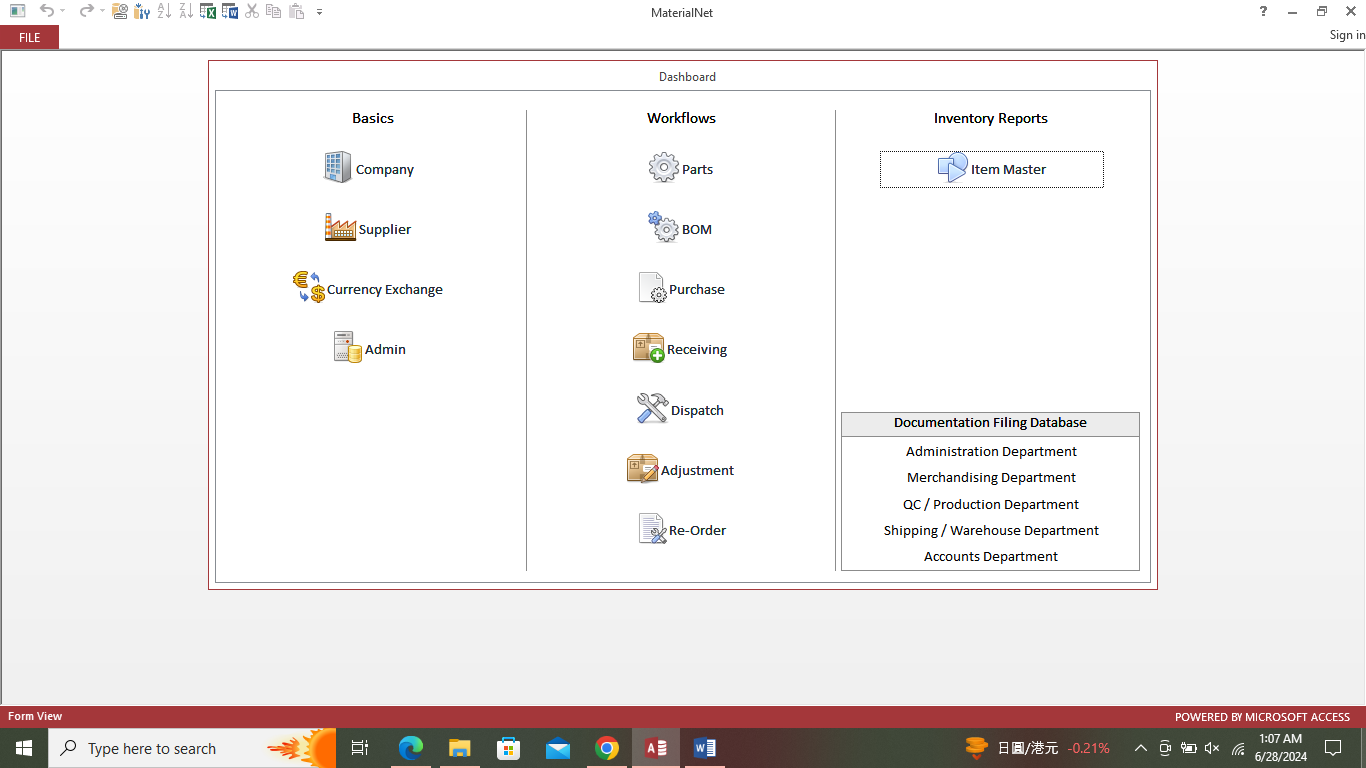

MaterialNet

Material Planning Software for Manufacturers

Control raw material inventory, dispatch with BOM, and prevent production delays

Who Uses MaterialNet?

Perfect for manufacturers managing raw materials and parts

Material Dispatchers

Control raw material dispatch to workshop with BOM tracking

Production Officers

Check inventory before production to prevent delays

Warehouse Managers

Track inventory levels and control purchasing decisions

What MaterialNet Does

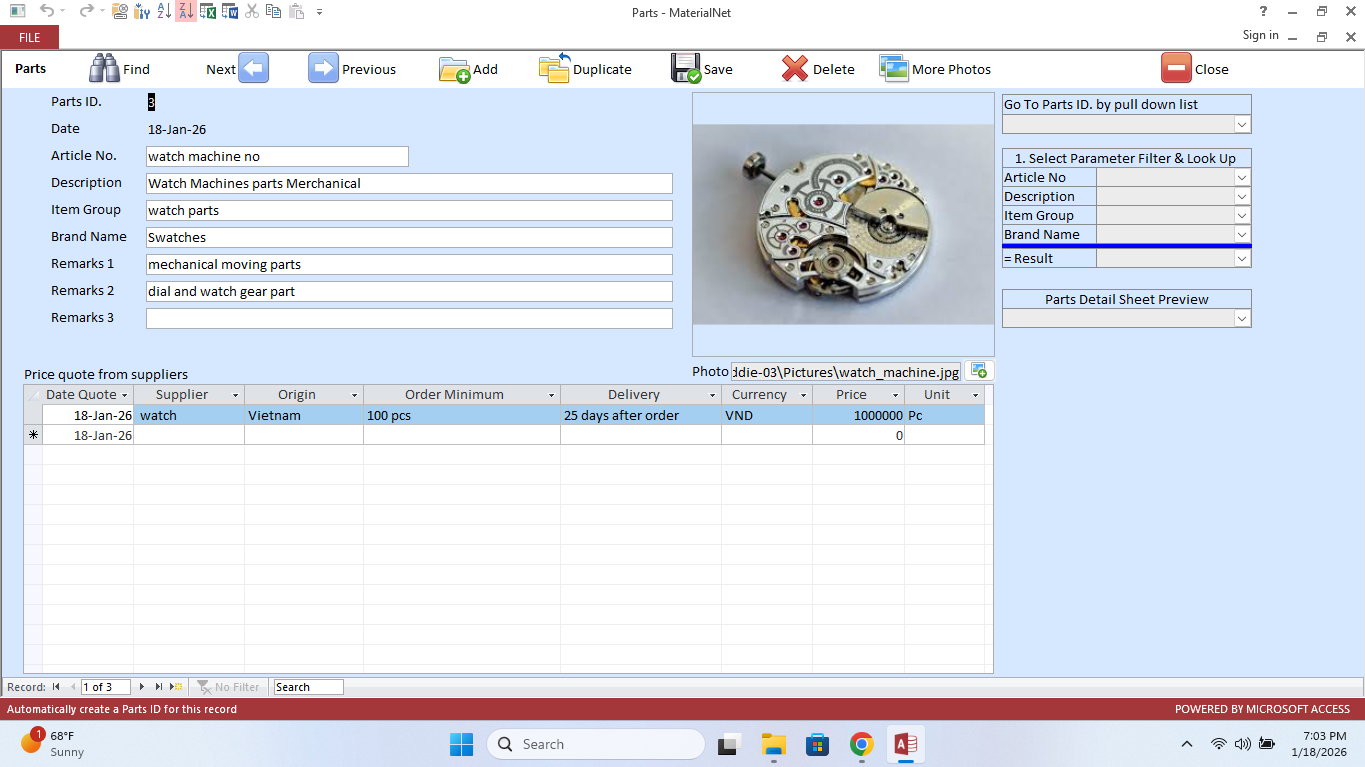

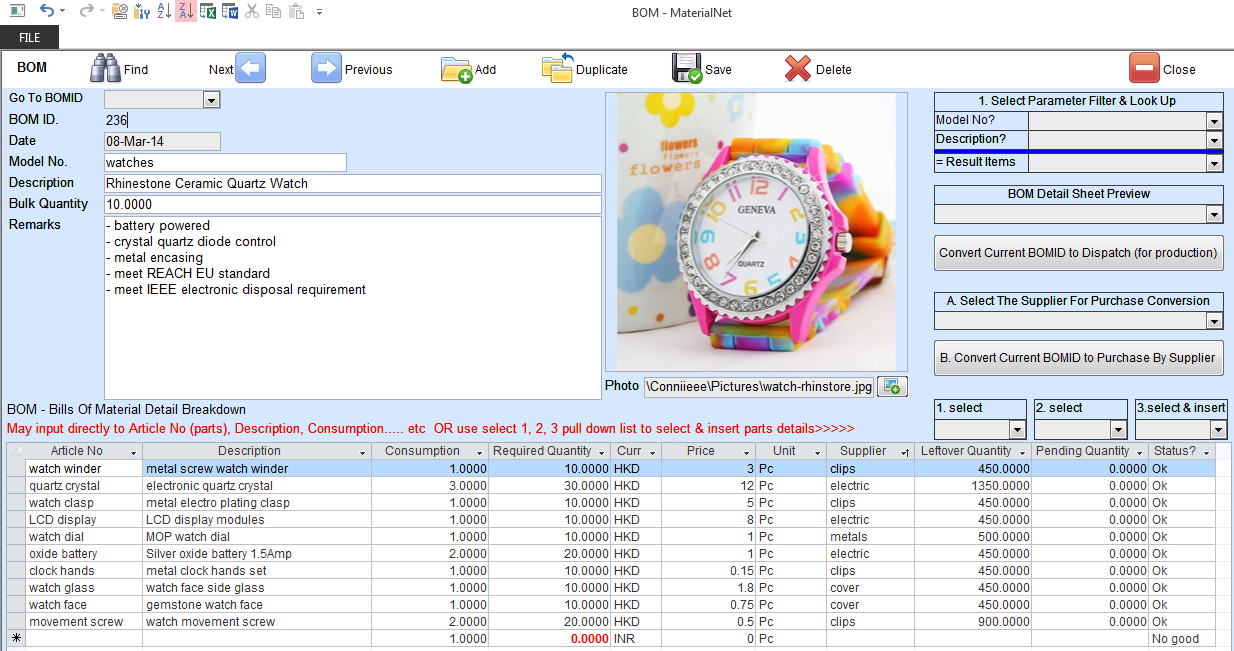

BOM Control

Use Bills of Material to control dispatch and ensure all parts are ready for production

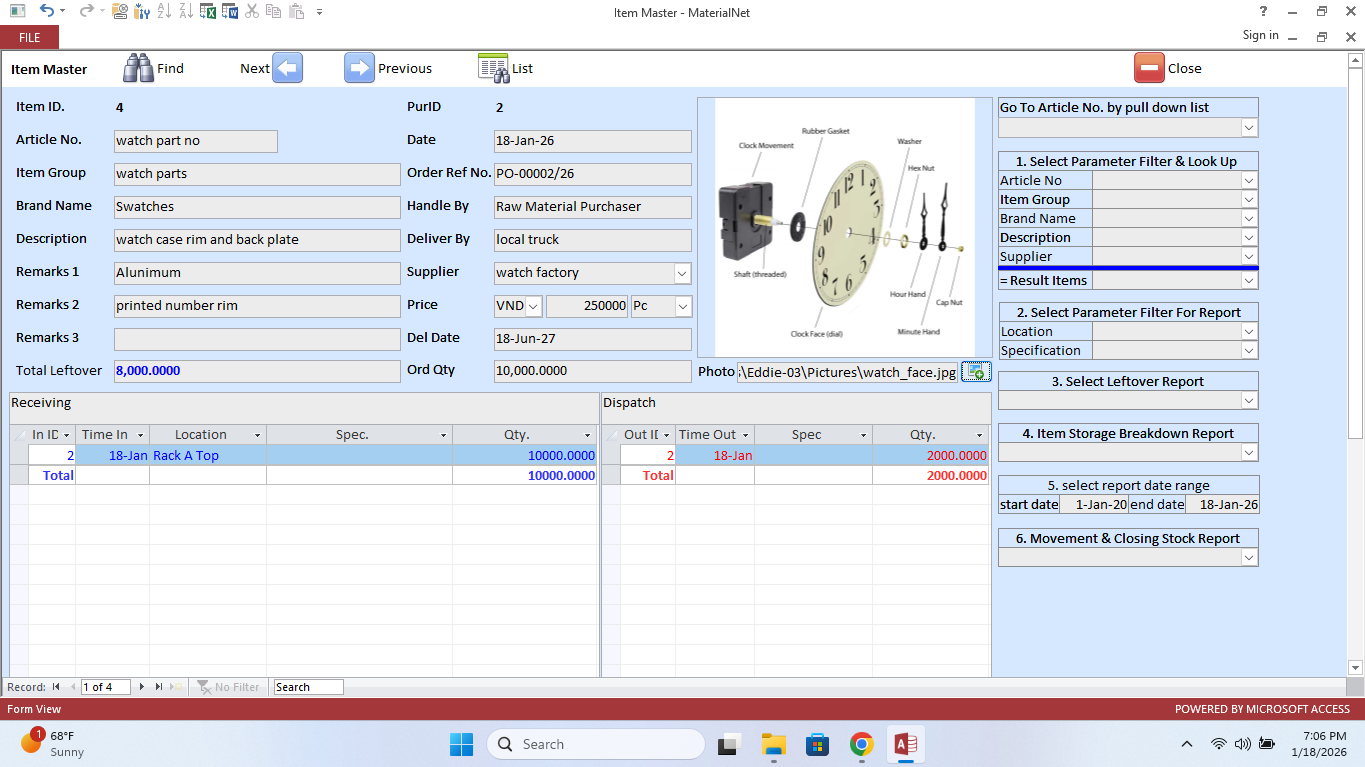

Real-Time Inventory

See exact stock levels of raw materials, parts, accessories and trims instantly

Expiry Alerts

Get notifications for time-limited items to avoid waste and expired materials

Smart Re-Order

Auto-calculate re-order levels with leftover and pending quantities

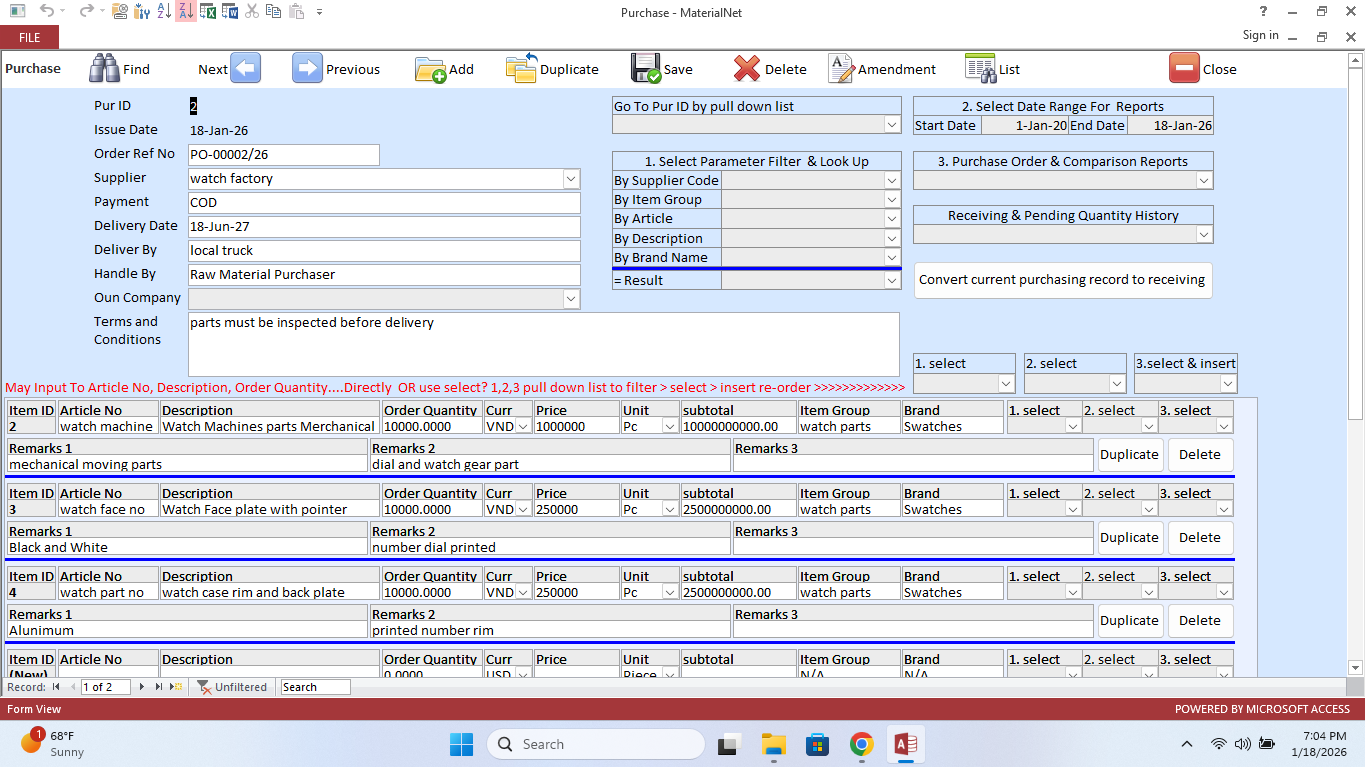

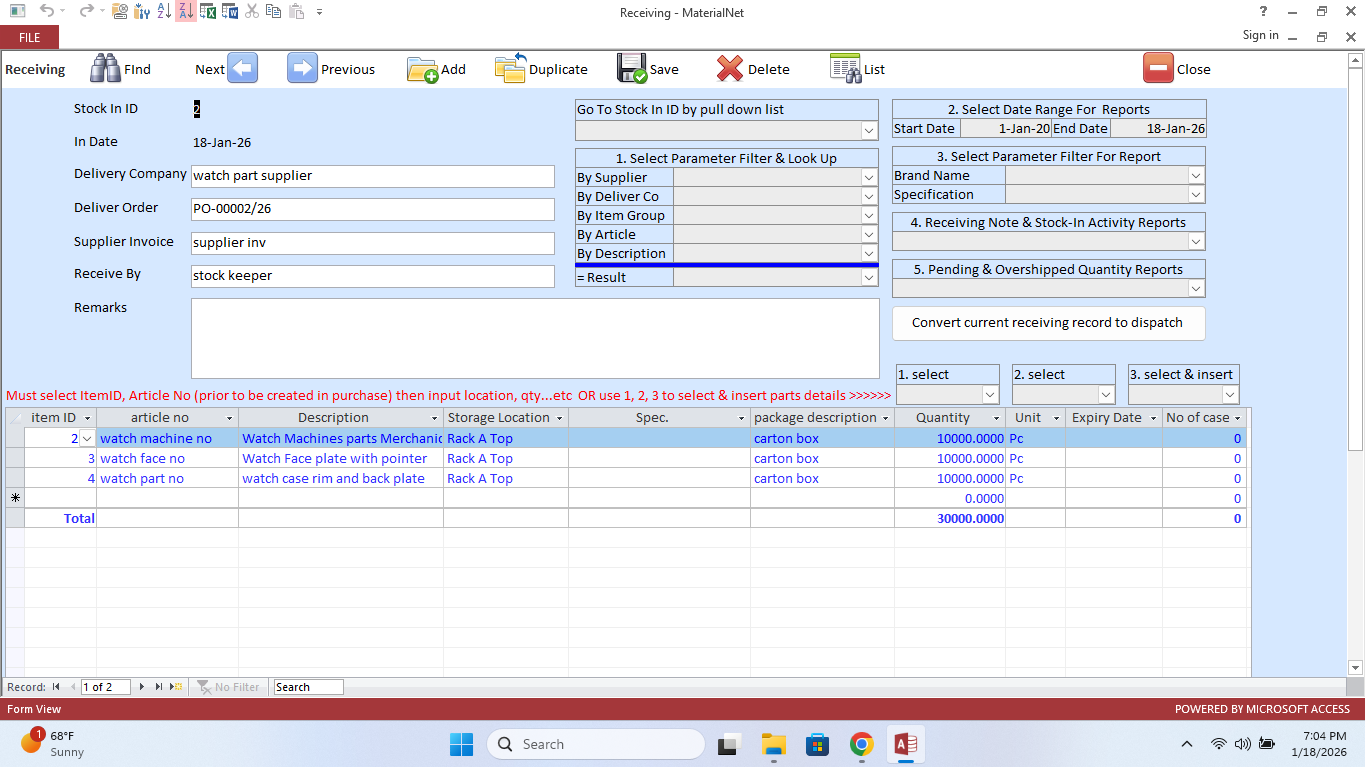

Purchase Management

Track all purchases, receiving, and vendor deliveries in one system

Cost Analysis

Compare BOM costs, purchasing and inventory to improve profit margins

How It Works

Create BOM

Set up Bills of Material for each product

Check Stock

Review inventory levels before production

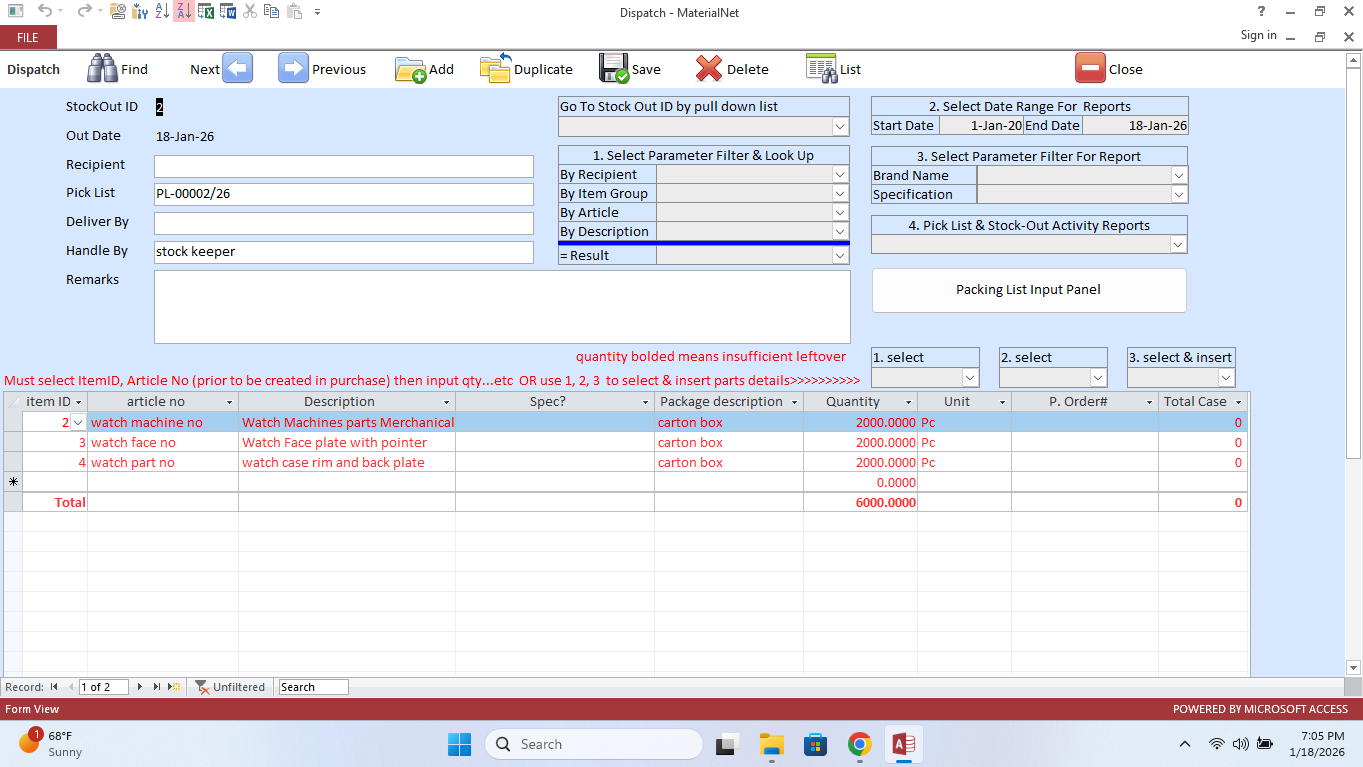

Dispatch Materials

Issue pick lists and dispatch to workshop

Track & Reorder

Monitor usage and reorder automatically

Without MaterialNet

- • Manual logbooks prone to errors

- • Can't see full inventory picture

- • Production stops due to missing parts

- • Over-ordering wastes money

- • Expired materials go unnoticed

With MaterialNet

- • Real-time digital inventory tracking

- • Complete visibility of all parts

- • Prevent delays with BOM checks

- • Smart re-order prevents over-stock

- • Automatic expiry alerts

Why Choose MaterialNet?

Zero Maintenance

No IT support needed. Just install and use.

Multi-User

Whole team can work together in one database.

Activity Logs

Track every change with full records.

Ready to Control Your Materials?

Stop production delays and reduce material waste today

Start with a free trial. No credit card required.